Laboratories and Testing Facilities

The Chair of Conveying and Material Flow Technology boasts extensive testing facilities for the practical research and optimization of bulk material conveying processes. Among the highlights is a 15-meter-long belt conveyor, which enables detailed tests and analyses under real-world conditions. This facility is complemented by a bulk material laboratory for investigating specific material properties, specialized test rigs for analyzing wear effects caused by bulk materials, and a crane simulator. Additionally, our high-performance simulation computers enable realistic bulk material simulations (DEM).

Visitors can take a virtual tour of our testing hall to get an initial glimpse and form their own impression of our research environment.

The test rig was designed to conduct experimental investigations into belt misalignment. Belt misalignment refers to the lateral position of the conveyor belt. The system is a 15-meter-long belt conveyor, comprising a horizontal test conveyor, a return conveyor, a hopper, and a chute.

Bulk material can be conveyed in a closed loop on this system. Various sensors capture the belt position, forces on the tension drum, and drive power. By flexibly adjusting the carrying rollers and the feed chute, specific disturbances can be introduced to study their impact on belt alignment.

Innovative Solutions for Wear Challenges in Conveying Technology

Wear is one of the critical limiting factors for the lifespan of conveying systems. Maximizing the efficiency and reliability of such systems requires an in-depth understanding of sliding and impact wear. This is precisely where our specialized laboratory comes into play.

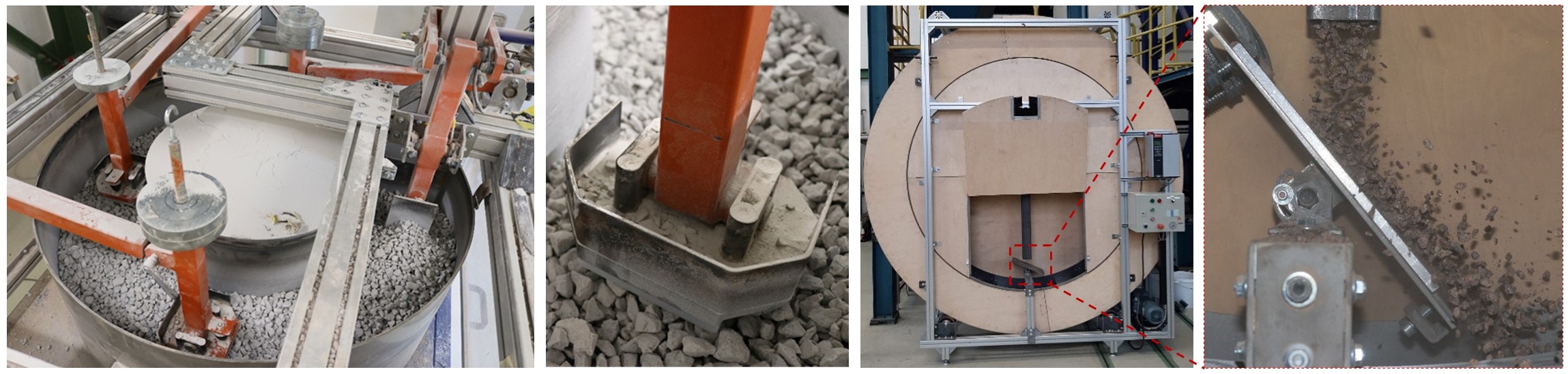

We offer the capability to precisely investigate sliding and impact wear under realistic conditions, tailored to various material pairings. Through our customized experiments, we not only determine accurate wear rates but also establish a foundation for the reliable calibration of simulations using the Discrete Element Method (DEM). These simulations are essential for analyzing, predicting, and ultimately minimizing wear-related challenges.

How can bulk materials be characterized?

Our bulk material laboratory is equipped with various tools to determine the properties of bulk materials. Among other things, density, wall friction, and internal friction can be measured using a Jenike shear test and a Schulze ring shear tester (RST-01.pc). The angle of repose is determined through a drawdown test, while particle size distribution is analyzed using a sieve tower. Additionally, the moisture content of bulk materials can be measured.

With the DrawDown and Rotating Drum test rigs, further parameters can be identified that are essential for calibrating bulk material behavior in simulations

What Is a Work Cycle, and How Do You Operate a Crane?

At our facility, interested individuals have the opportunity to try this out on our crane simulator! Our crane simulator is a detailed, digital replica of the overhead crane in Building 11.2. Here, both experienced and novice crane operators can test their skills and familiarize themselves with crane controls—completely risk-free and in a realistic environment.

The simulator offers a hands-on experience of the fascination and precision involved in operating a crane.